Full Truckload Shipping 101: Trailer Types, Quoting and Loading

02/15/2023

Shipping via full truckload (FTL) is one of the most common shipping methods when arranging the transportation of a large volume of freight. Truckload shipping is an excellent solution if the shipper has enough freight to fill at least half of the full trailer capacity, which commonly translates to more than seven standard pallets. Here are some truckload shipping tips from our logistics experts to help you master everything from quoting to loading.

Most commonly, when shipping via full truckload, there are three types of trailers:

- – Van

- – Temperature Controlled (Reefer)

- – Flatbed

Van trailers are used for general freight, while reefer trailers are used for freight that must be kept at or below a certain temperature.

When should full truckload shipping be used?

Full truckload shipping is most commonly used based on a volume threshold of more than seven standard pallets of freight. However, full truckload shipping can also be used when faster transit times or a decreased possibility of damage is needed. Truckload shipping helps deliver goods to the end destination more quickly than Less-than-Truckload (LTL) shipping. This is due to truckload freight being shipped directly from origin to destination without freight being transloaded at the carrier’s service hubs.

How much does it cost to ship a full truckload?

The total cost to ship a full truckload ranges based on a variety of factors, including the length of haul, market conditions, lane volume & current fuel surcharges as well as potential pickup or delivery accessorials.

Some of the most common truckload shipping accessorials are:

- – Lumper services (loading and unloading)

- – Detention

- – Pallets

Additionally, how quickly the freight needs to arrive can impact the rate. For example, hiring a team of drivers increases the rate, but serves as an excellent option when shippers need freight to be delivered more quickly than standard transit. Seasonality can also impact truckload rates as there are peak shipping seasons that cause rates to increase in the spot market.

How does rating and quoting work for full truckloads?

Shippers are increasingly using technology, enabling them to gather quotes more quickly and compare multiple truckload bids at once. However, old-school methods are still widely used across the industry, allowing shippers to call or email for a quote.

Similar to other modes of transportation, there are standard shipment details that must be provided before receiving a quote from a carrier or broker. The typical response time can range between minutes and hours dependent on the carrier and method used to request the quote.

Basic shipment details needed for a quote are:

- – Origin and Destination city, state and zip code

- – Pickup date and delivery date

- – Equipment type

- – Commodity

- – Weight

How many pallets can fit in a full truckload?

Dependent on the type of freight, shippers can typically fit between 24 and 30 pallets in a full 53′ van or reefer trailer.

It is important to note that weight will dictate how much freight can be transported in the trailer, along with whether or not the pallets are stackable. For example, if the freight is fragile, the pallets will not be able to be stacked, limiting the total amount of freight that can be transported. Typically, cargo weight cannot exceed 46,000 pounds for a van, 44,000 pounds for a reefer and 48,000 pounds for a flatbed.

Are there best freight loading practices?

Yes, freight should be distributed over the three axle groups, which include the steer, drive and trailer tandems. The weight applied to each axle should be double-checked and distributed evenly. For example, the fifth wheel and trailer tandems can be adjusted to redistribute weight among axle groups to maximize payload while still complying with axle weight limits. Additionally, it is best practice to load the heaviest freight toward the front of the trailer.

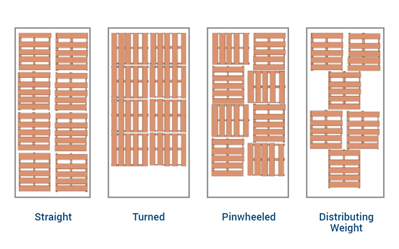

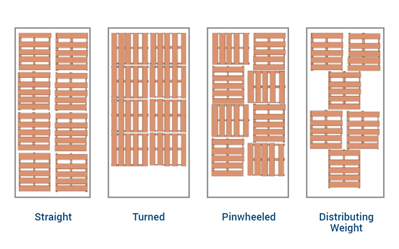

There are also four standard pallet loading configurations, including straight, turned, pinwheel and distributed weight, as seen in the graphic below.

Who said logistics had to be complicated? We certainly didn’t. Learn more about our truckload solutions and get a free, no-obligation quote for shipping your goods.

6 Reasons to Outsource Logistics

March 11, 2024

Thank you for contacting Ascent!

A member of our team will be in contact within a few business hours.

Okay